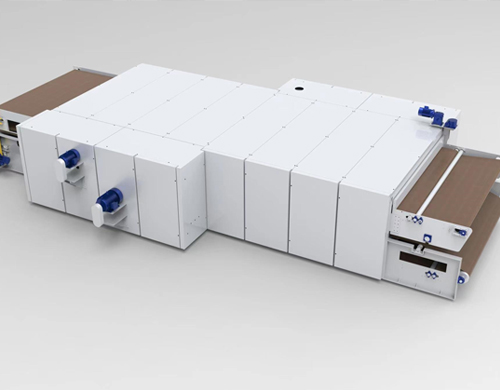

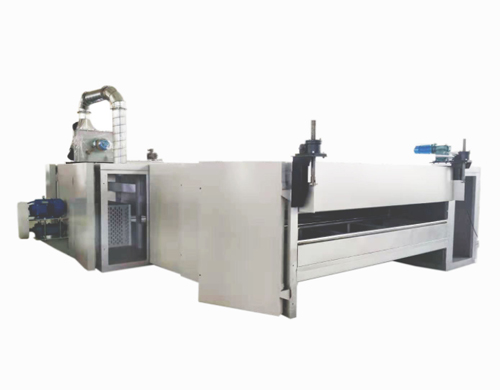

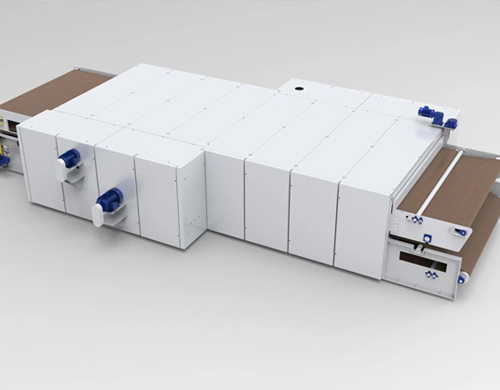

HJHF-Drying Oven

2) Technical parameters: The fan is controlled by two 7.5KW motors and four 5.5KW motors to control its air volume. The uniform air supply insulation board is made of cold-rolled plate, the middle insulation body is made of aluminum silicate material, and the thickness of the insulation board is 100mm , a total of 4 layers of processing area length 4000-12000MM, width 3100MM

Total weight: 12 tons

3) Machine overview:

(1) The control adopts frequency conversion, and the transmission adopts stainless steel mesh and curtain rod

(2) The hot air circulates through convection, blowing up and sucking down; the air duct is a drawer-type structure, which is easy to pull out the air duct insert for cleaning and hanging flowers. The main structure is made of frame type (angle iron) cold plate

(3) The front and rear glue spraying pools are made of stainless steel plate and stainless steel tube with a diameter of 25*1.2MM

(5) Heating method of drying room: heating tube (electric heating)